- 首页

- 公司简介

- 产品中心

- 下载中心

- 支持与服务

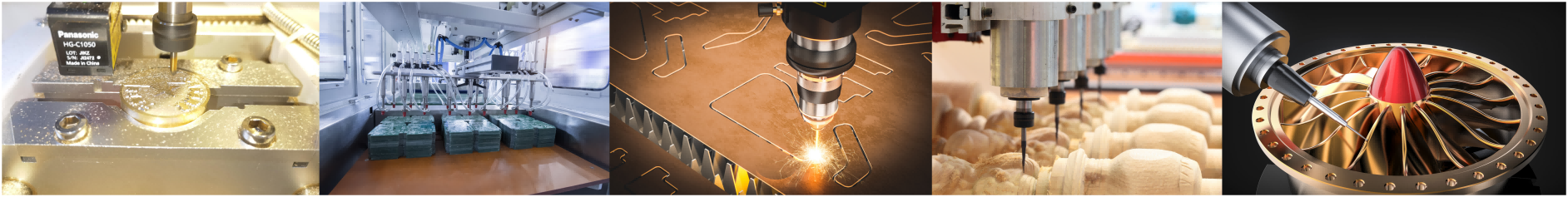

- 行业应用

行业应用

赛科五轴系统核心优势概述

🌟 赛科五轴系统核心优势概述

CYCLMOTION 5-Axis CNC System — Core Advantages Overview

一、高精度 · 一键复原

Ultra Precision · One-Touch Restoration

系统具备正交补偿与标准球标定功能。

正交补偿让 XYZ 线性轴重新建立精准的几何基准;

标准球标定通过拟合自动计算旋转轴的真实中心与倾角补偿,使旋转轴方向与空间坐标完全一致。

即使机床在客户现场重新装配,也能通过一键标定恢复出厂精度,无需工程师上门。

五轴机的安装与调试,从此像三轴机一样轻松,真正实现“出厂精度可复原”。

The system features orthogonal compensation and standard-sphere calibration.

Orthogonal compensation reestablishes precise geometric alignment of XYZ linear axes,

while the standard-sphere calibration automatically computes the actual rotary centers and inclination compensation,

ensuring perfect alignment between rotary axes and the spatial coordinate system.

Even after reassembly at the customer’s site, the machine can restore factory-level accuracy with a single calibration — no technician required.

Five-axis setup and tuning are now as simple as a three-axis machine, achieving truly restorable factory precision.

二、数字孪生 · 虚拟装配

Digital Twin · Virtual Assembly

全新的虚拟机台系统,可在电脑中完整还原真实机床。每个部件都可自由装配、运动与校准,实现“所见即所得”的数字孪生体验。

无论是调机验证、程序仿真,还是教学展示,都能在虚拟环境中完成,省时、安全又直观。

The new virtual machine system fully recreates the real CNC in a 3D digital environment.

Each component can be assembled, moved, and calibrated interactively, offering a true “what-you-see-is-what-you-get” digital twin experience.

From setup verification and simulation to training and demonstration — everything can be done virtually, safely, and efficiently.

三、安全可控 · 智能防护

Smart Safety · Real-Time Protection

系统内置实时碰撞检测功能,可自定义检测对象与安全逻辑。

当检测到潜在碰撞时,可自动触发 IO 输出,实现虚拟探测、报警或限位保护。

这让五轴仿真不仅可看,更能参与安全联动,提前发现风险,保障设备与人员安全。

The system includes real-time collision detection with fully customizable monitoring pairs and safety logic.

When a potential collision is detected, the system automatically triggers IO outputs to simulate probing, alarms, or limit stops.

This makes the simulation not only visual but interactive — identifying risks before they happen and ensuring both equipment and operator safety.

四、开放集成 · 全面兼容

Open Integration · Full Compatibility

系统兼容 AC、BC、CA、AB 等多种五轴结构,可灵活适配不同机型与控制方案。

所有模块——从标定、补偿到仿真与 IO——都在同一数据体系下运行,轻松对接教学、监控、远程管理等上层系统,构建完整的智能制造生态。

The system supports multiple five-axis configurations such as AC, BC, CA, and AB,

allowing flexible adaptation to various machine types and control architectures.

All modules — calibration, compensation, simulation, and IO — operate within a unified data framework,

enabling seamless integration with teaching, monitoring, and remote management platforms to form a complete smart manufacturing ecosystem.

五、创新易用 · 专业可靠

Innovative & Intuitive · Professional & Reliable

从机床标定到虚拟仿真,从路径规划到安全防护,系统实现了一体化、可视化、自动化。

用户无需复杂配置,即可体验工业级控制精度与教学级操作便捷。

From calibration to simulation, from toolpath planning to safety protection,

the system achieves full integration, visualization, and automation.

Users can enjoy industrial-grade precision with educational-level simplicity — no complex setup required.

在线咨询 - 下载中心